Our own custom-built boat

Atlas Boatworks is a semi-custom boat builder. That means that we build the hull, center console, and livewell (essentially all the fiberglass parts) the same every time. Then you, as the customer, get to do the fun part. You get to choose all the accessories and finish out the boat the way that you want to. Well, for our 2024 Demo Boat, we get to be the customer.

Follow along through the next several blog posts as we walk through what we’ve chosen and why. We will also talk a little about the process of building semi-custom boats and how we do things.

Choice Numero Uno: Hull Color

We are big fans of white boats. In fact, we wrote a whole blog post here about just hull color in which we professed our love for white hulls. So, when it came time to pick the color for our demo boat, it was a no-brainer.

But, which white?

Now, if you’ve ever looked at paint chips, you know there is not just one shade of white. There are lots. Like, literally hundreds. So, how do you choose? We went with a softer white color. The main objective was to have a white that wasn’t a super bright because the reflection from the sun is really hard on the eyes after a full day on the water. We want something toned down a bit.

You Choose

Hull, center console, and livewell colors are some of the color choices that you get to make as you go through the design process. Ultimately, you decide and we build it. If you want to see all the other choices you get to make, try our Build a Quote tool and put together your perfect custom boat.

The Next (First) Step

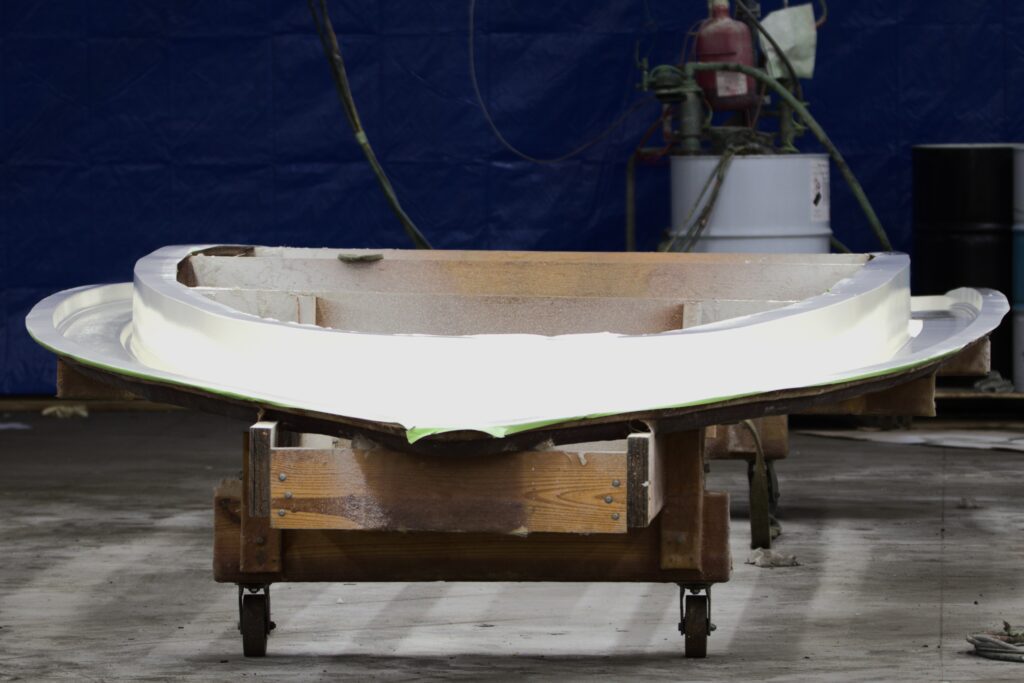

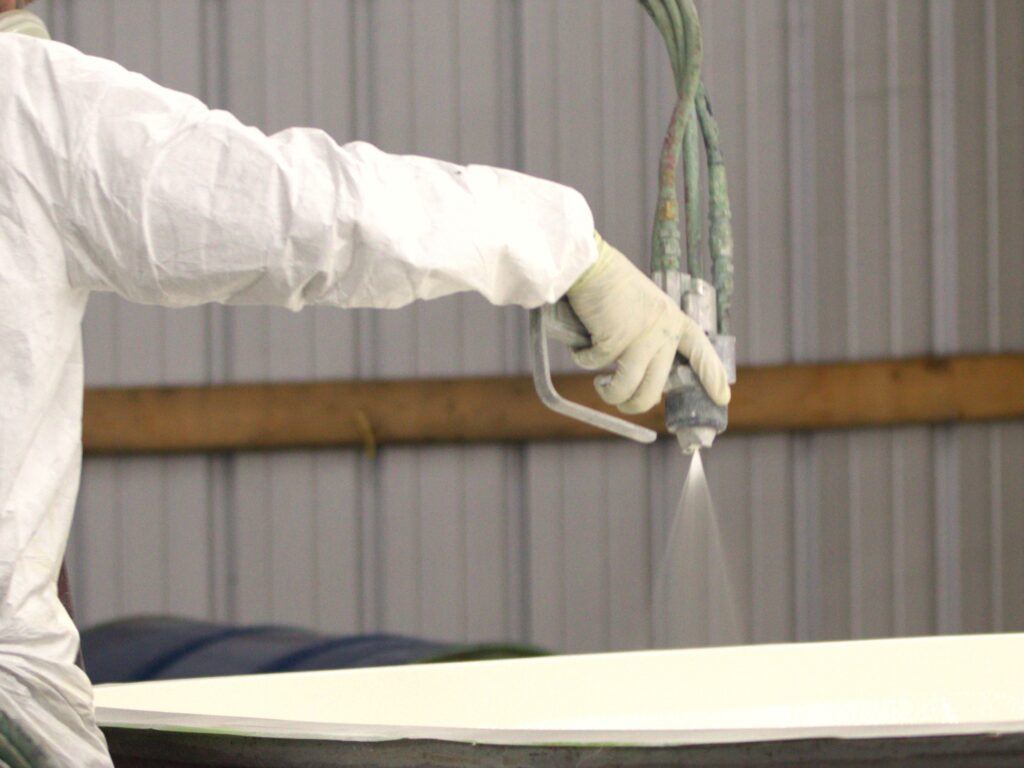

After you choose the gelcoat color, the next step is actually getting it in the mold. First the mold is cleaned and waxed to produce a smooth, slick, surface. Then the gelcoat is sprayed into the mold to the desired thickness. Measurements are taken all around the hull to ensure that the gelcoat is the correct thickness.

Lastly, the rest of the parts get sprayed with gelcoat. This includes the deck cap, center console, livewell, and hatch lids.

Next Time

For our next post, we will dive into the skin coat, which is the next layer after the gelcoat. Brace yourself, it’s gonna be a doozy. Stick with us as we continue, step-by-step, through the building of our 2024 Atlas Boatworks Demo Boat.