Keepin' On

Alright, as promised in our last post, we are continuing the journey of our 2024 demo boat by talking about the different types of fiberglass that we have used. If you missed that post then back up the bookmobile and go back here and check it out.

There are 3 types of fiberglass that we use to build the Atlas Boatworks 23F: chopped strand (or just “Chop”), 1708, and 2408. Now, the reality is that we already covered chopped strand in a previous post, so rather then repeating ourselves, we’re just going to send you back to read it here if you want. It is in the gray section called, “Chopper Gun: A Dirty Word?” Now, if that doesn’t pique your interest, I don’t know what will.

Stick with us below as we talk about 1708 and 2408 and what all this mumbo-jumbo means.

Why does it matter?

The whole point of the fiberglass is to provide structural stability to the resin. The resin is a 2-part mixture that, when combined, creates a thermal reaction and gets super hard. By combining long, continuous, strands of fiberglass in the resin you get significant strength at a relatively light weight. You can’t have one without the other.

With the Atlas Boatworks 23F, we combine a few different types of fiberglass cloth to build an ideal strength-to-weight ratio for the stated purpose of the boat (Epic inshore fishing trips with the occasional dabbling offshore on calm days). Based on what they want to do with the boat, boat builders combine different “Layups” of materials to meet their goals. This can include multiple layers of cloth, coring material (foam or polyester), and different types of resins. Those goals are a combination of weight, strength, cost, speed, unique properties, and ease of building.

But what do the numbers mean?

First, it is important to understand that the fiberglass cloth is actually two cloths stacked on top of each other. There is a woven one on top of a chopped one. Once you know that, it is pretty easy. The first numbers, ie the “17” in 1708 is the weight (thickness) of the woven portion and the last two numbers (the 08 in our example) is the weight of the chopped part.

So a piece of 2408 is heavier (thicker) than a piece of 1708. There are tons of different combinations, all with their own properties and applications. Common ones are: 1208, 1708, 1808, 2408, and 3610.

Plot Twist

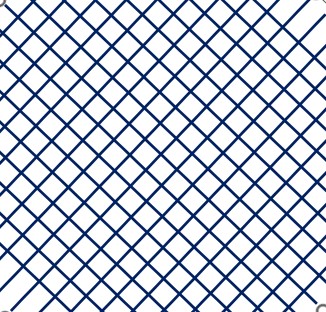

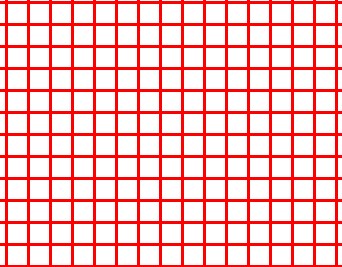

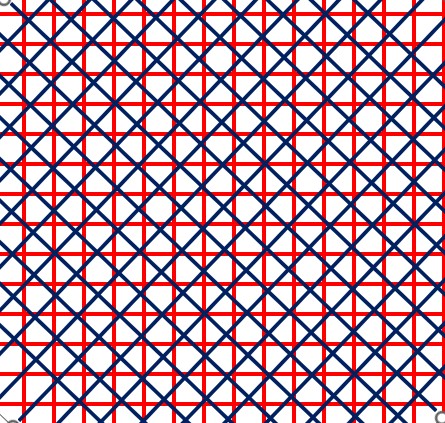

There is one more thing that differentiates the different types of fiberglass cloth besides just weight. That is the direction of the fibers. Our 1708 has fibers that run on the 45-degree axis, whereas our 2408 fibers run on the 0/90- degree axis. If you overlap the two you get fibers that run in almost every direction which provides strength regardless of the direction of the load. Check out our rudimentary drawing below.

So, with that basic knowledge, you know just enough to be dangerous and ask really annoying questions to your boat builder. Should be fun.

Next Time

Join us next time when we dabble in the world of small parts. Consoles, livewells, hatches, and other miscellaneous sundries. We’ll ask the question, “Does size really matter?” when building boat parts.